Call us: +386 (0) 5 330 03 60 | Write to us: info(at)mordicom(dot)si

SBL - Smart Bakery Line

Wednesday, 25. 2. 2026

MordiCom d.o.o. is developing SBL - Smart Bakery Line for Gostol-Gopan ltd.

The cooperation started as a consortium of companies with an application for the SBL Research and Development Project within the tender "Incentives for Research and Development Projects 2", co-financed by the Republic of Slovenia and the European Union from European Regional Development Fund. Following the succesful completion of the RD project in early 2020, cooperation continues.

Project Smart Bakery Line consists of:

- Processing of data coming from meters and sensors on the bakery line. Data collection and processing is performed on a dedicated server on the line. The mixture of processed and raw data is transmitted to the servers that subscribe to it. Part of the data storage takes place in the Google cloud, and part in the computer center at Gostol-Gopan.

- SBL portal, which is intended to display the collected data

Near real time display

- Information of current batch and recipe

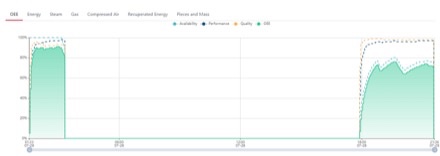

- Current OEE information

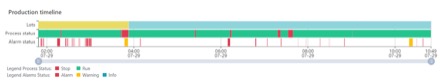

- Current line status showing batches and unused parts of the line

- Current date production progress

- batches

- statuses of the current date production process

- alarms with reasons

- the time course of the current batch on the line showing the line stops and stops types

- current date batches

For select period

- Cumulative data for

- OEE

- Produced quantities and ejections

- Production flow in the selected period

- batches

- production process statuses

- alarm statuses

- Energy consumed by sources

- Electricity

- Gas

- Compressed air

- Steam

- Recuperated energy

- Graphical time display for OEE, energy consumed by types, recuperation, quantity / mass of products produced

- Batch data for the period

Data can be printed or exported in various formats for further processing.

Analysis of energy consumption

- by types and various criteria for the selected period

Diagnostics

- Alarm statistics

- Duration timeline

- Occurence timeline

- Analysis of alarms by frequency of occurrence and duration on individual machines

Maintenance and service

- Graphical display of hardware maintenance tasks and services

- Task agenda

- Missed tasks

- All tasks

- Daily maintenance tasks

- Tasks according to calendar

- Task agenda

- Report entering on completed tasks

Video line surveillance

OEE

(Overall Equipment Efficiency)

(Overall Equipment Efficiency)

Production timeline

SBL

(Smart Bakery Line Dashboard)

(Smart Bakery Line Dashboard)